It seems that their 2x9 connector could also match you system. If you prefer the exact connector type and title I'd advise to begin with investigating the machine where by the connector is located and looks at The seller's website. If they have got tech guidance you could mail them and question. Share Boost this reply Comply with

Compactus Connectors Compactus Sealed Hybrid Connectors are sturdy, substantial-density, automotive-quality connectors that allow makers to fit more energy and signal transmission skill into a small space.

Galvanic corrosion at connection factors: Aluminum, metal and zinc will normally corrode when in electrical connection with copper. Copper will frequently corrode when in contact with stainless steel or brass. This could certainly weaken connections after a while.

A further the latest problem got me serious about this. Will a floor to the frame get the job done correctly When the bolt is powder-coated?

The probability of me damaging a connector on account of ignorance is way better than hurt ensuing from old age. Check with me how I am aware.

Copper's linear thermal growth coefficient is about 17 micrometers / meter / diploma C (off the highest of my head, it is possible to seem it up nevertheless).

stAK50h Connectors Leveraging marketplace-authorised terminal structure, the stAK50h Connection Technique offers unsealed hybrid headers and receptacles to provide both equally signal and Ethernet connectivity within a smaller footprint

Is there anything at all that one can do to hold off the onset of wire embrittlement? Wouldn't it assistance if companies use a different quality/gauge of wire to assist with longevity?

Actual copper failure is more probably to occur in the vicinity of link factors. Out of your description you've possibly operate into both of those. Silicone insulation is a sensible choice for that. Any relationship issue copper failure the thing is, though, are only one of those car connectors inevitabilities. I could not notify what you intended by "introduce a split" so I just took the shotgun approach.

Which is environmental temperature in addition temperature from The existing flow. 70°C can easily be achieved under the hood as well as while in the cabin. Due to vibrations, I'd say installation in an automobile isn't mounted, And so the lower limit is a lot more -5°C than -forty°C.

NoobPointerExceptionNoobPointerException 11122 bronze badges two Thanks for worthwhile remedy. The IDC is a good idea but I'm afraid I will need thicker wires compared to common Computer IDE cables :).

You should purchase a spray can of undercoating and spray your link place with that just after your relationship is manufactured. Paint operates also, but undercoating is somewhat versatile and will not likely crack like paint will In the event the connection is issue to any flexing.

@JasonC The engine bay is hotter because the ability for warmth for being absorbed via the environment is lowered. Having said that, I was not informed that electrolysis could Enjoy a job here.

the solution to the types of stresses that wiring normally undergoes within an ecosystem like an motor bay.

Neve Campbell Then & Now!

Neve Campbell Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Erik von Detten Then & Now!

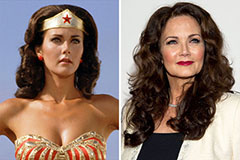

Erik von Detten Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now!